Planograms have been the standard approach to planning merchandising for decades. But as more and more retailers are discovering, planograms just aren’t up to the realities of merchandising today: more frequent store resets and promotions, store teams stretched thin, and HQ investments in big data tools to drive greater localization and optimization.

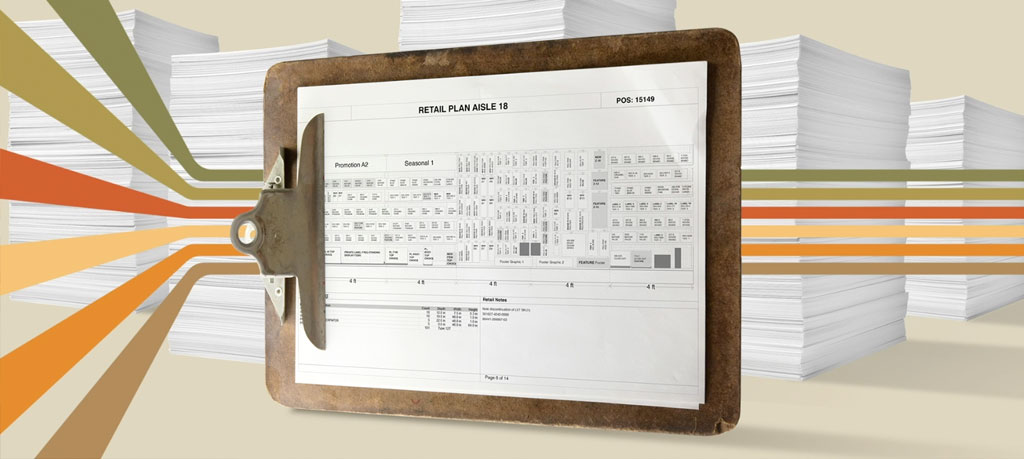

In this dynamic retail environment, store teams need to act quickly to execute merchandising plans—and they need to get them right. But store teams often struggle to decode what a planogram is telling them to do or find that the amount of product shown in a planogram won’t actually fit on the shelves. Meanwhile, they may not even be working off the correct or most recent planogram in the first place. Many times, store teams are given thick binders full of documents and planograms, not all of which apply to their specific store. Planograms emailed or posted on the company intranet can easily be missed.

And when merchandising plans can’t be executed properly or efficiently, there’s a cascade of real business consequences:

- Inefficient use of labor. Labor hours are wasted as employees puzzle over hard-to-understand planograms, go back and forth between the store floor and the back room, and re-set shelves that have been improperly set the first time. Retailers report an average of 40+ hours per week of lost time spent merchandising that could be better invested in serving customers.

- Unhappy employees. When setting shelves is an exercise in frustration and confusion, employees become disgruntled, leading to less-than-friendly customer service and high staff turnover.

- Poor customer experience. With poorly set displays, customers can’t find what they’re looking for, nor are they drawn to new products or promotions. If you’re lucky, they’ll give you another chance. If not, they’ll turn to one of your competitors instead.

- Strained relationships with brands. Promotions don’t pack they punch they should when they’re not executed accurately, and brands are left wondering why their products are underperforming.

- Unanswered questions about performance. Retailers can’t accurately measure performance and fine tune their merchandising and product assortments accordingly because they don’t know whether planograms were correctly executed. There’s no basis for analysis, and no way to be strategic about merchandising choices going forward.

As if all that isn’t problematic enough, there’s also the high cost of printing and shipping all those planograms.

It’s time for retailers to think beyond the traditional paper planogram, toward a modern, dynamic mobile-ready solution—one that shows store teams only the plans pertinent to their specific store, along with step-by-step guidance and built-in tools for flagging issues and verifying compliance. Our platform from One Door delivers all of that and more. To learn about our dynamic, digital planograms, download the eGuide